As we all know by now, offsite build and modular technology is very much en vogue. With the recognition that the complexity of traditional construction processes carry with them inherent and residual risks in terms of cost, efficiency, health & safety and environmental aspects the move towards the factory built environment is gaining momentum.

Our vision is to make people happy

It has long been the dream of the construction industry to be able to replicate the lean, efficient and precision built principles of factory manufacturing into the sector and the plethora of benefits they would bring.

Whilst it is difficult to challenge the benefits of this new industry philosophy, there is also an industry mindset to overcome. The decision to take the leap of faith and go down the offsite build route involves a value judgment on behalf of the buyer that must take into account the whole project cost and the benefits that these products can bring such as superior quality, programme reductions, consistency, sustainability etc.

So, how best to communicate the cost savings of sound value engineering?

How best to make the industry realise that there are truly revolutionary bespoke products, delivered in quick time, which can be installed and connected in minutes?

How best to highlight the features of factory built quality, that has been designed and tested and is manufactured offsite using the latest available technology anywhere in the World?

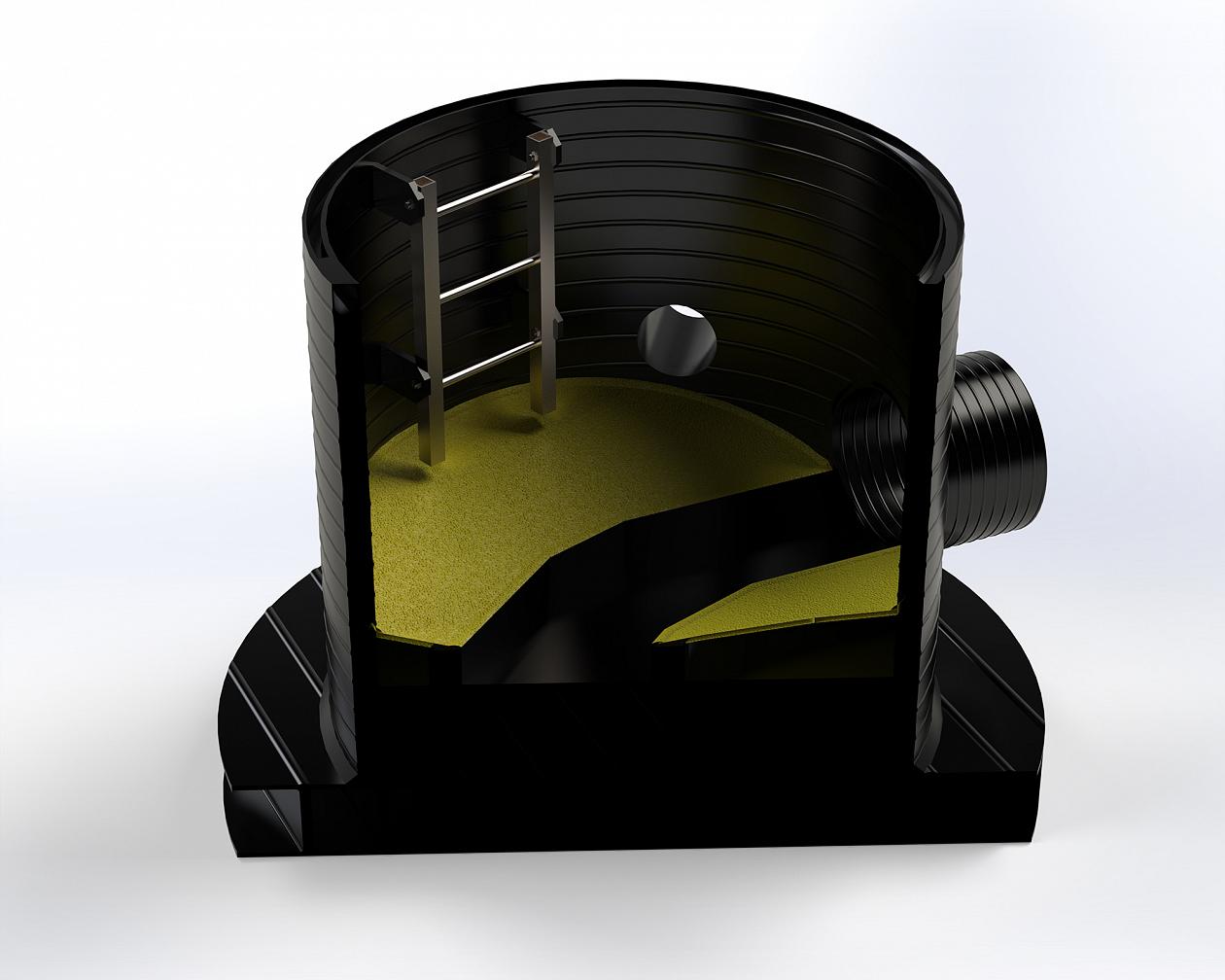

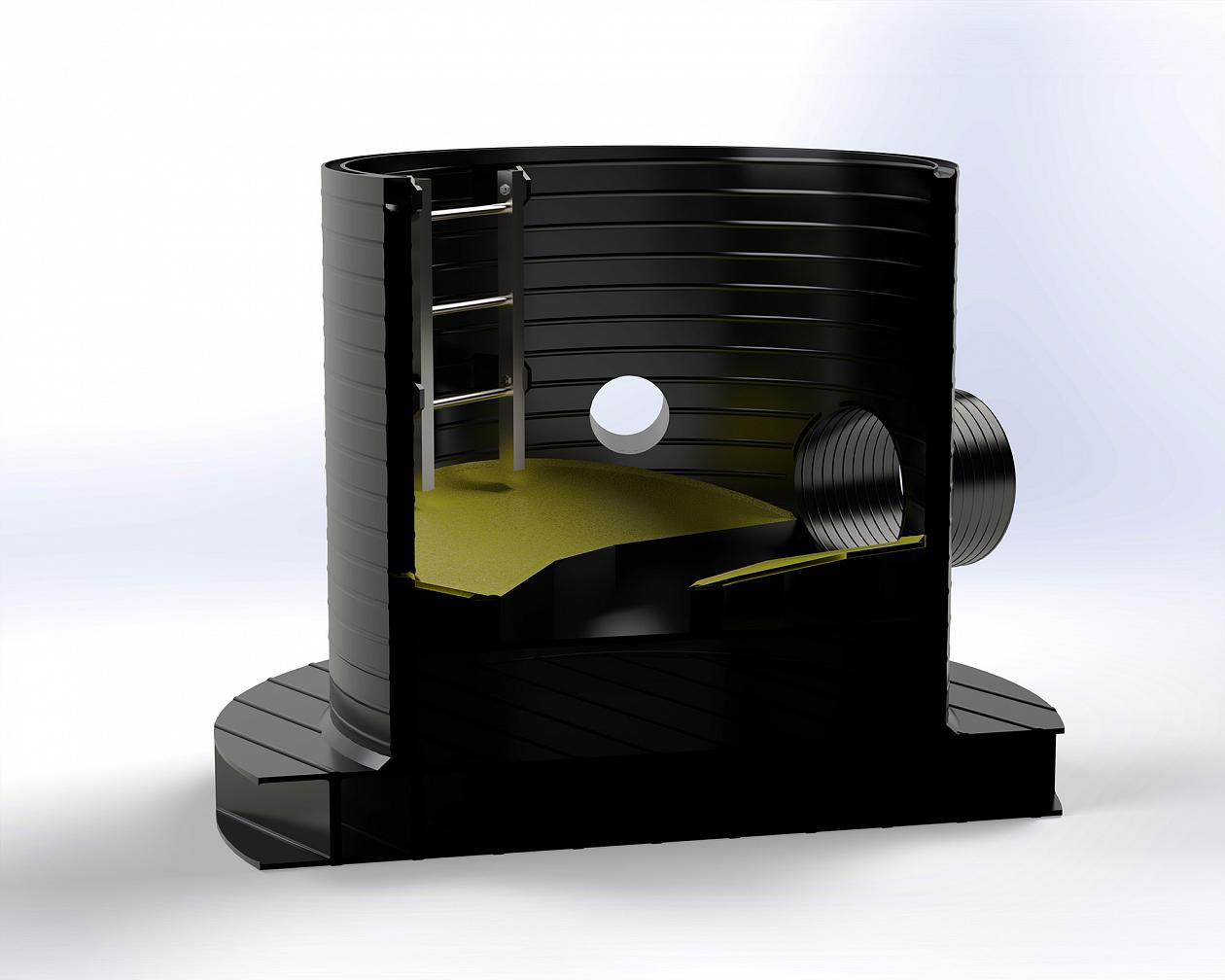

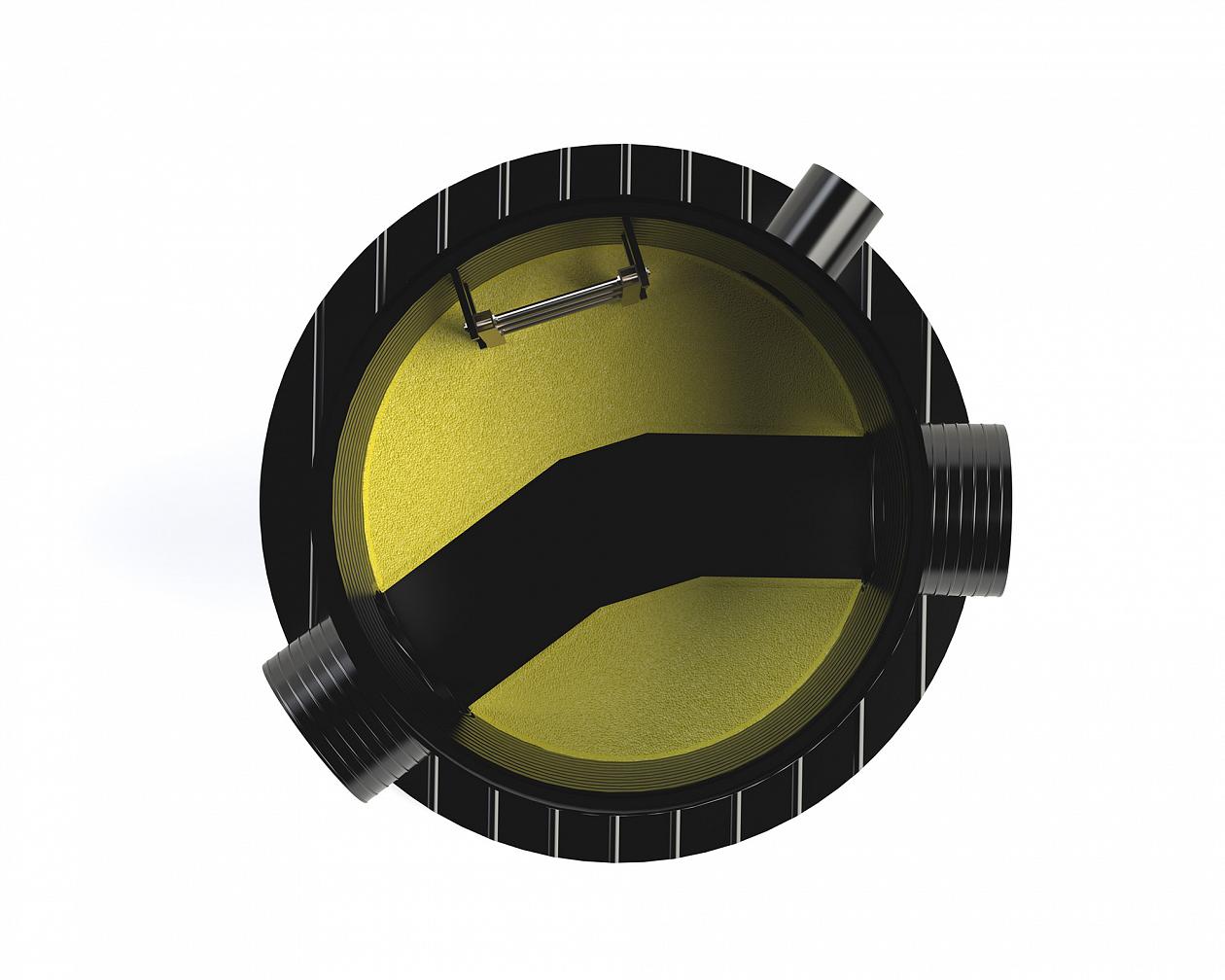

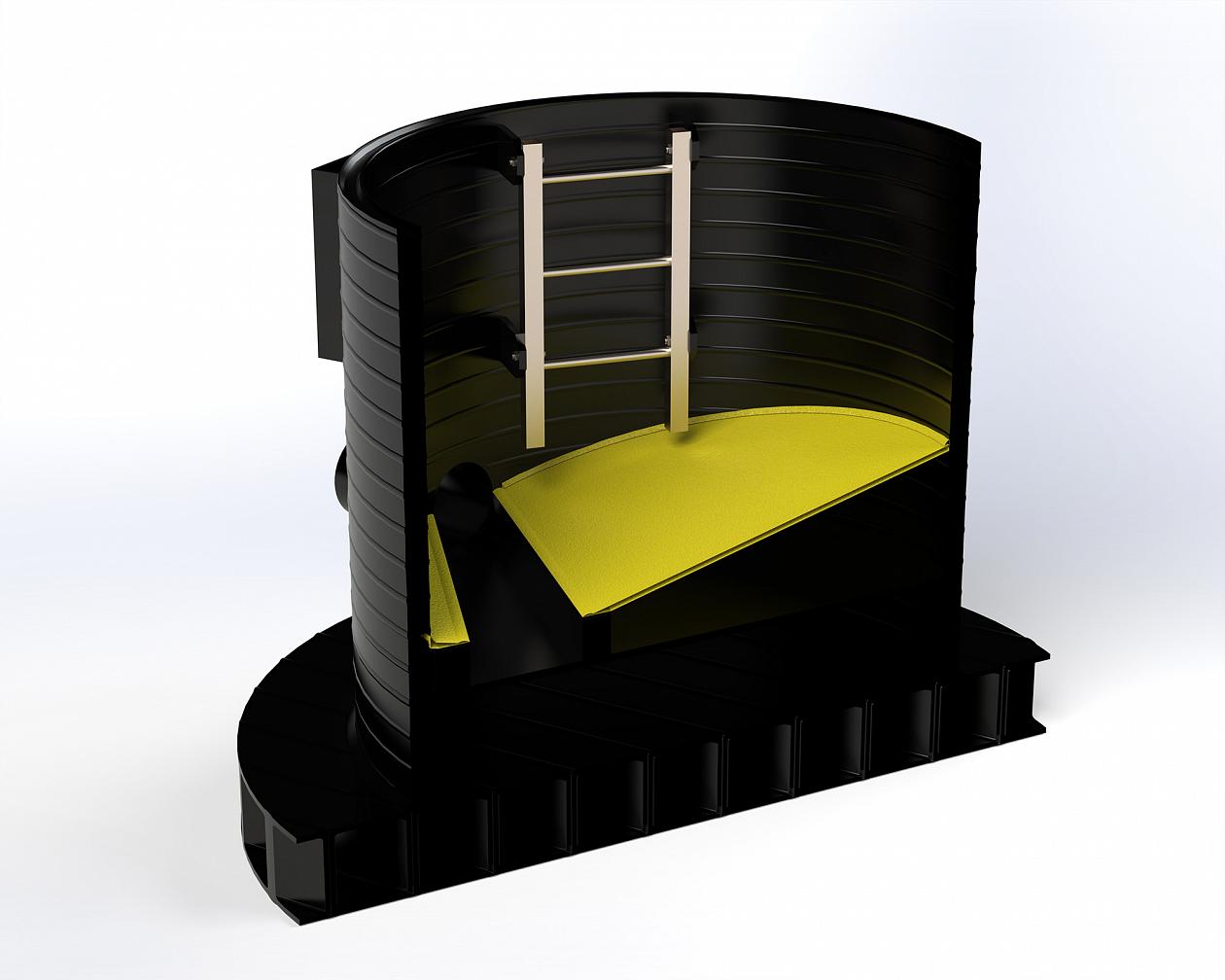

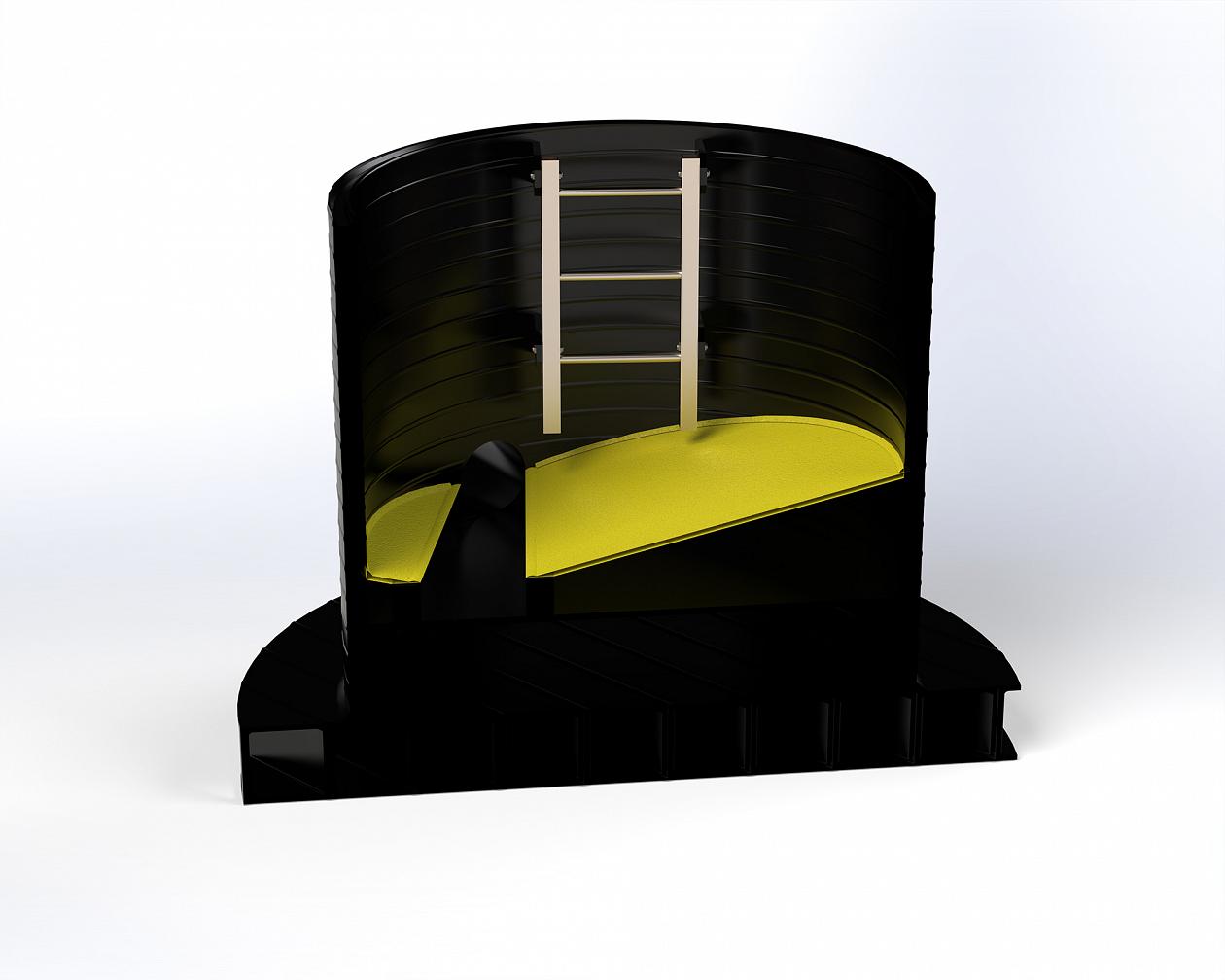

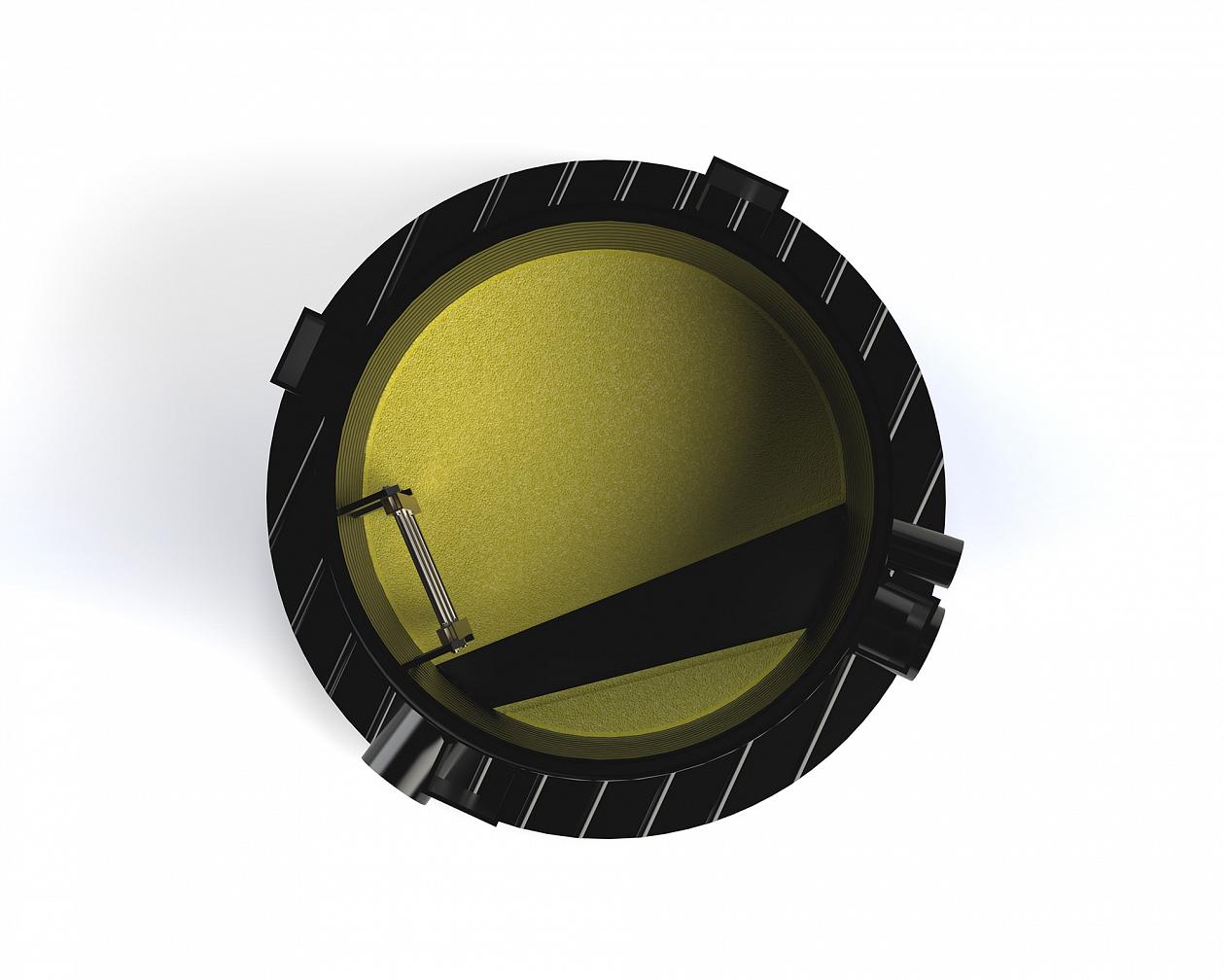

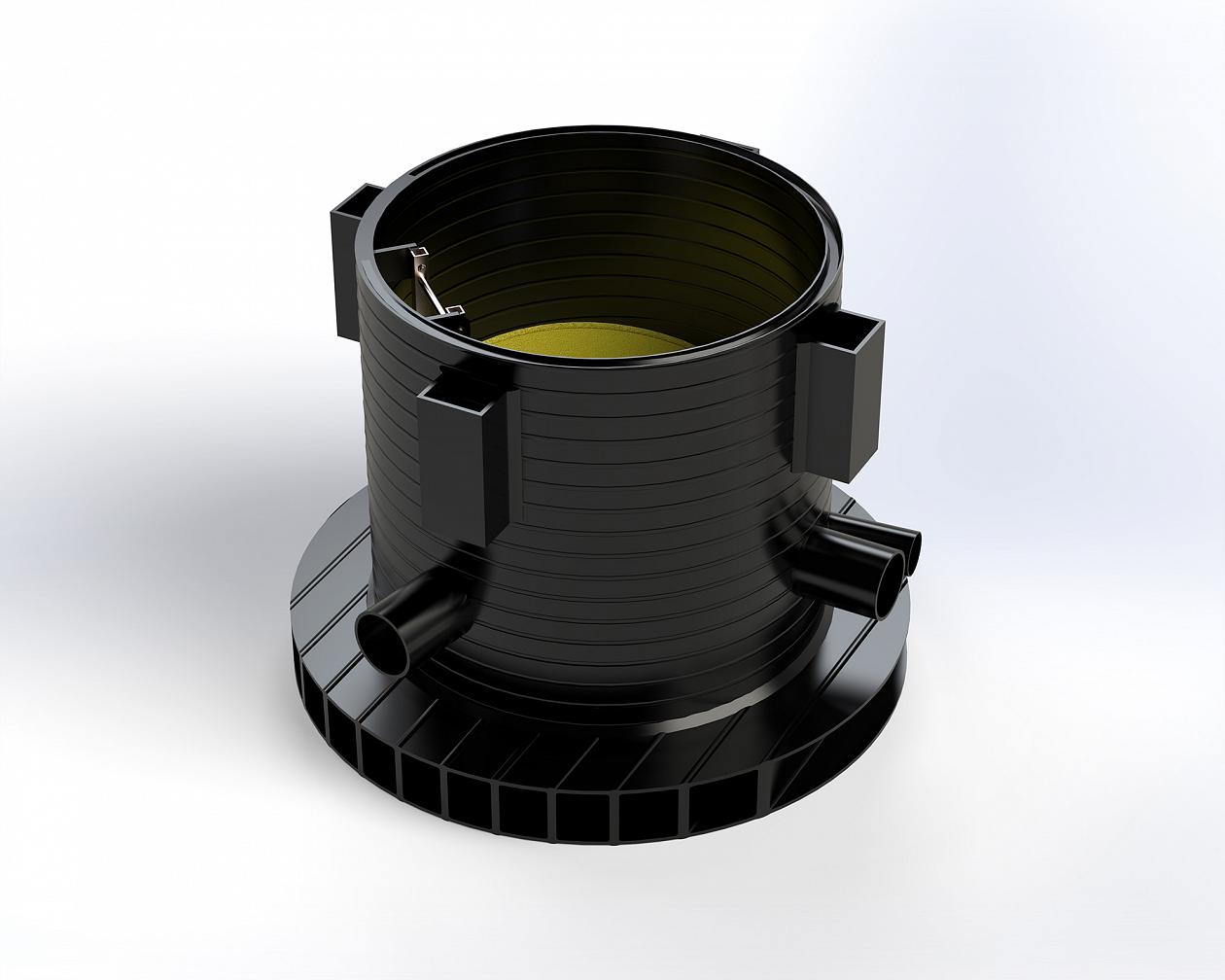

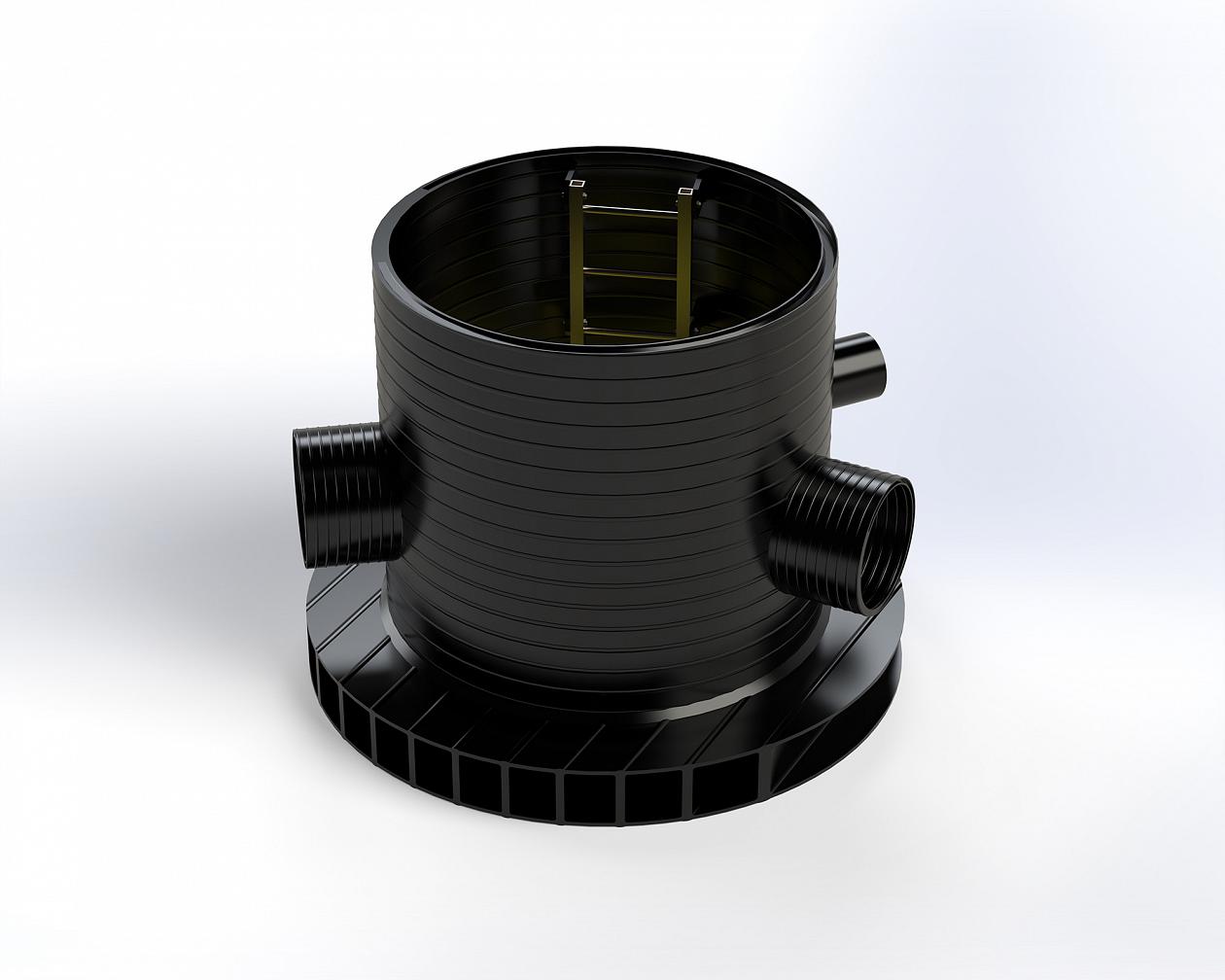

If ever there was a flagship product that truly represents the offsite build philosophy it is Weholite manholes.

Benefits of Manholes

- Savings on programme

- No concrete surround

- Fully air tested and 100% watertight

- No rocker pipes needed

- Manholes and chambers ready to use immediately

- Fully tested lifting points

- Totally resistant to Hydrogen Sulphide

- Lighter plant and less labour needed

- HDPE has the best abrasion resistance

- Special anti-slip benching factory fitted

- Better flow properties

- Very low maintenance